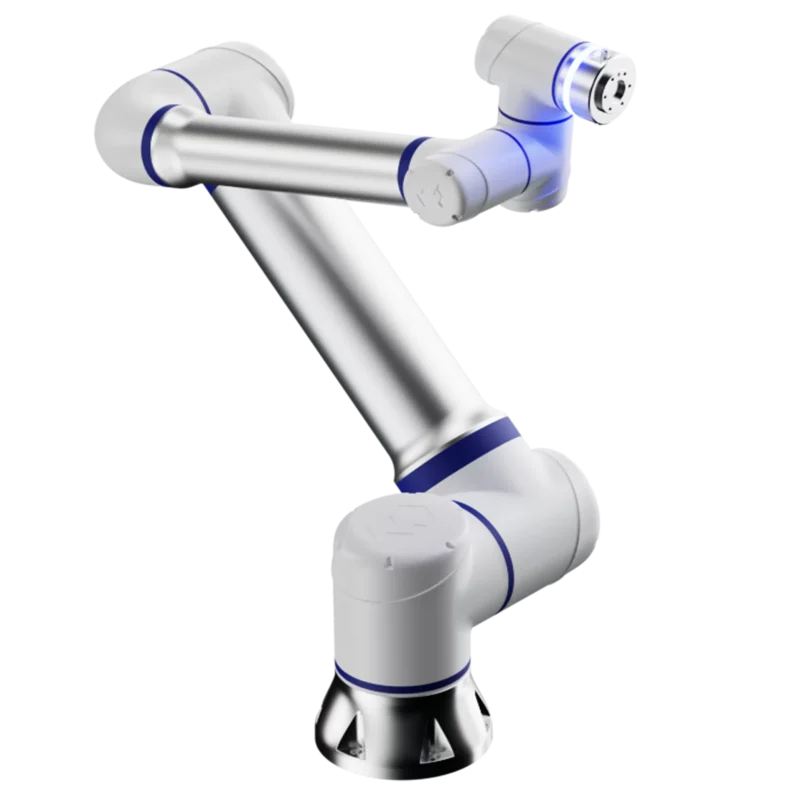

ELITE Collaborative Robot

Pain Points in the Industry

Skilled labor shortages

High mix/low volume production

Staff reliability

Health & safety concerns

Cobots can perform tasks faster and more accurately than humans, which can improve productivity and reduce costs. Cobots can also operate 24/7 and don’t need breaks or holidays. This frees up employees to focus on other tasks that require human skills. Collaborative robots, often referred to as cobots, are advanced robotic systems designed to work alongside humans safely and efficiently. Their integration in various industries enhances productivity, flexibility, and worker safety. Cobots incorporate sophisticated safety features such as force-limiting technology and sensors to prevent collisions, making them suitable for close collaboration with human operators in shared workspaces. They come in different types—like articulated arms, mobile platforms, and ELITE robots—each tailored for specific tasks such as assembly, packaging, and quality control in automotive, electronics, and logistics sectors. Manufactured by specialized companies, these robots operate through advanced programming and sensor technologies, enabling seamless interaction with humans. Looking ahead, the future of cobotics holds promise with ongoing advancements in AI, machine learning, and human-robot interaction, driving further innovations in grippers, vision systems, and connectivity for enhanced industrial automation solutions.

Elite Robots offers sturdy, lightweight 6-joint robotic arms for versatile collaborative tasks. With an IP68 protection rating, they handle up to 25 kg payloads and extend up to 1900mm. Their controllers are highly expandable, supporting custom plugins and multiple programming languages. Featuring an intuitive graphic UI and a virtual platform for simulation, they include an embedded palletizing application wizard for quick deployment. Backed by a wide network of integrators and OEM partners, Elite Robots provides flexible automation solutions, from single installations to large-scale projects.

Effective in work Area

Top Choice For Advance Automation

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis |

CARRY WEIGHT - 3kg |

MAXIMUM REACH - 624mm |

POINT TO POINT ERROR- ±0.02mm |

MAXIMUM SPEED - 2.0 m/s |

STANDARD PROTECTION - UPGRADABLE

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis |

CARRY WEIGHT - 6kg |

MAXIMUM REACH - 914mm |

POINT TO POINT ERROR- ±0.03mm |

MAXIMUM SPEED - 2.8 m/s |

STANDARD PROTECTION - UPGRADABLE

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis |

CARRY WEIGHT - 12kg |

MAXIMUM REACH - 1304mm |

POINT TO POINT ERROR- ±0.05mm |

MAXIMUM SPEED - 3.4 m/s |

STANDARD PROTECTION - UPGRADABLE

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis |

CARRY WEIGHT - 25kg |

MAXIMUM REACH - 1500mm |

POINT TO POINT ERROR- ±0.08mm |

MAXIMUM SPEED - 3.3 m/s |

STANDARD PROTECTION - UPGRADABLE

Wide Range Industry Application

Pick & Place

Machine Tending

Quality Inspection

AGV mobility

Palletizing

Screw Driving & Assembly

Dispensing

Material Removal & Finishing

Smart Retail

Others

Cost Effective Cobots

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis | CARRY WEIGHT - 3kg | MAXIMUM REACH - 624mm | POINT TO POINT ERROR- ±0.02mm | MAXIMUM SPEED - 2.0 m/s | STANDARD PROTECTION - IP54

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis | CARRY WEIGHT - 6kg | MAXIMUM REACH - 914mm | POINT TO POINT ERROR- ±0.03mm | MAXIMUM SPEED - 2.8 m/s | STANDARD PROTECTION - IP54

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis |

CARRY WEIGHT - 16 kg |

MAXIMUM REACH - 954 mm |

POINT TO POINT ERROR- ±0.03mm |

MAXIMUM SPEED - 2.8 m/s |

STANDARD PROTECTION - IP54

Collaborative Robot (COBOT)

DEGREE OF FREEDOM - 6 Axis |

CARRY WEIGHT - 4kg |

MAXIMUM REACH - 1900mm |

POINT TO POINT ERROR- ±0.01mm |

MAXIMUM SPEED - 4 m/s |

STANDARD PROTECTION - IP54